Specialty Chemicals

Our products help improve industrial manufacturing processes

Scanditronic Technology supplies specialty chemicals to manufacturers of electrical and electronic components and other applications. These chemicals can either be used standalone or as part of a formulation.

Since these chemicals are crucial to your production process, purchase them from a reputable company like Scanditronic Technology to safeguard the quality of your end products.

Types of specialty chemicals we supply

Epoxy resins

Our product is suitable for and commonly used by LED package makers. Our epoxy resins are used as an encapsulant with other LED package components. Within the LED encapsulation, besides epoxy resin, phosphor and other chemicals will be mixed together.

Nano hollow silica fillers

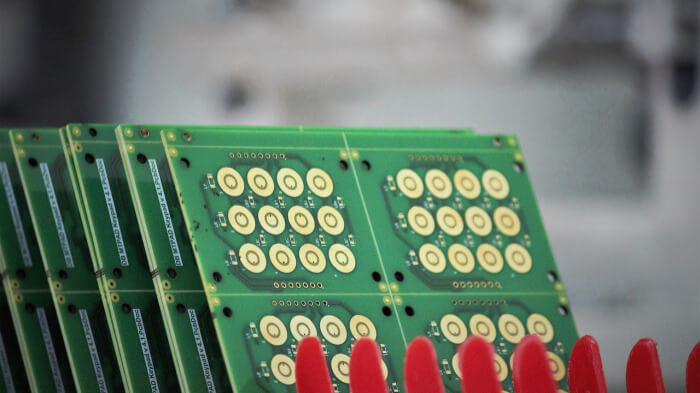

Nano hollow silica filler is a special grade of silica filler used for epoxy moulding compounds. Epoxy moulding compound (EMC) effectively shields semiconductor circuits from harsh factors in the external environment, such as moisture, heat, and shock.

EMCs usually contain fused silica fillers. However, using nano hollow silica fillers instead of fused silica fillers can improve the durability of the chemical compounds.

Nano hollow silica filled epoxy moulding compounds are also preferred for small devices and circuit boards. Many electronic companies require EMCs to act as a shield for the delicate inner core of their products.

Polyethylene & polypropylene

Polyethylene (PE) and polypropylene (PP) are the 2 most common polymers in plastic injection molding. Polyethene and polypropylene are made mainly from ethylene, a by-product of natural gas processing. The 2 materials are often combined to create a material with a longer shelf life and better heat resistance.

You can find polyethylene in many applications because it can withstand high temperatures without melting. In addition, its strength and flexibility make it ideal for use in protective clothing and medical devices.

Polypropylene is often used in packaging because it is waterproof and flexible. It also has excellent chemical resistance when exposed to acidic or basic solutions. What’s more, it can be molded into almost any shape necessary for its application using heat or pressure presses.

Companies often use both chemicals in the plastic injection industry. You can also see them in use for sectors like automotive and construction or any industry that requires durable materials resistant to chemicals.

Ultra pure electronic chemicals

Ultra pure electronic chemicals are specialised types of chemicals used in the semiconductor industry. Ultra-pure electronic chemicals need purity of more than 99%.

These chemicals are used for tasks like cleaning wafers and etching silicon dioxide layers in printed circuit boards and other semiconductors. They are also used in manufacturing photovoltaics semiconductors, LED flat panel displays, and lithium-ion batteries.

Ultra pure electronic chemicals are commonly found in the semiconductor, hard disk drive, and solar production plants.

Ion exchange resins (IER)

Ion exchange resins are used to soften and purify water to user specifications. The resins bind to impurities and remove them from the water. Some of these resins are also used as synthetic adsorbent in the food and beverage industry.

Various industries such as semiconductors, power plants, food production, pharmaceuticals, and oil and gas use IER for water purification. For example, mixed with resins, activated charcoal can remove organic contaminants, such as chloride.

IERs are also commonly used to clean up samples in a lab – a technique known as column chromatography. Pharmaceutical companies often use them in the drug and therapeutic development process.

Flocculant

A flocculant is a compound added to a vessel. It makes the particles stick together to create larger particles.This is the process of flocculance.

The process causes the solution to separate, so it’s often used to remove the sediment from a fluid. The term comes from “floc”, which means flakes of material. When a solution is flocculated, the deposit forms larger aggregated flakes which either float to the surface or sink to the bottom, making them visible for removal.

Flocculants are used in various industries and applications to extract suspended solid matters from wastewater. In this treatment, solid waste is coagulated and separately removed. As a result, wastewater is neutralised for discharge.

These chemicals are also used for lime softening, sludge thickening, and solids dehydration. So, any industry that has to go through wastewater treatment must use flocculants.

Why buy specialty chemicals from Scanditronic Technology

Specialty chemicals are used across a wide range of industries. If you’re looking to purchase specialty chemicals, get them from Scanditronic Technology. Here’s why:

- We source our products only from reputable manufacturers and run strict quality checks on them. We know that the ingredients will affect your final products so we ensure what’s sold is in the right specification, quantity, and quality.

- We offer prompt delivery so that you can get your orders quickly and easily. Any manufacturing delay reduces revenue and profitability, so we make sure to process orders as fast as possible so you can start production.

- Our responsive after-sales support means that if anything goes wrong with your order or it doesn’t meet your required specifications, we’re here for you! We’ll work diligently with you until the issues are fixed.

Contact us

India

+91 7397561213

+91 9663365557

sales@scanditronic.com.sg

Office hours

Monday – Friday: 9 a.m. – 5:30 p.m.

Singapore

+65 8823 6607

sales@scanditronic.com.sg

Office hours

Monday – Friday: 9 a.m. – 5:30 p.m.